We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

As the temperatures drop and the days grow shorter, many may assume that the work of a bee farmer comes to a halt during the winter months. However, here at BS Honey Bees Ltd, we can assure you that our work is far from over when the bees are treated and tucked in for winter. In fact, the winter season is a crucial time for us, as it's when we lay the groundwork for the upcoming beekeeping season.

Let's take a closer look at what goes on behind the scenes during the winter months:

1. Frame Assembly:

Even during winter, there's no rest for our hands. We begin by assembling frames, essential components for our hives. This meticulous task ensures that we have a sufficient supply of frames ready for the busy season ahead.

2. Cleaning and Re-waxing Frames:

Old frames are given a new lease of life as we meticulously clean and rewax them. This process not only maintains the hygiene of our hives but also ensures the structural integrity of the frames.

3. Gluing and Folding Correx Bee Transport Boxes:

Attention to detail is key as we carefully glue and fold correx bee transport boxes. These boxes play a vital role in safely transporting our bees, protecting them during transit ready to go to customers all over the UK.

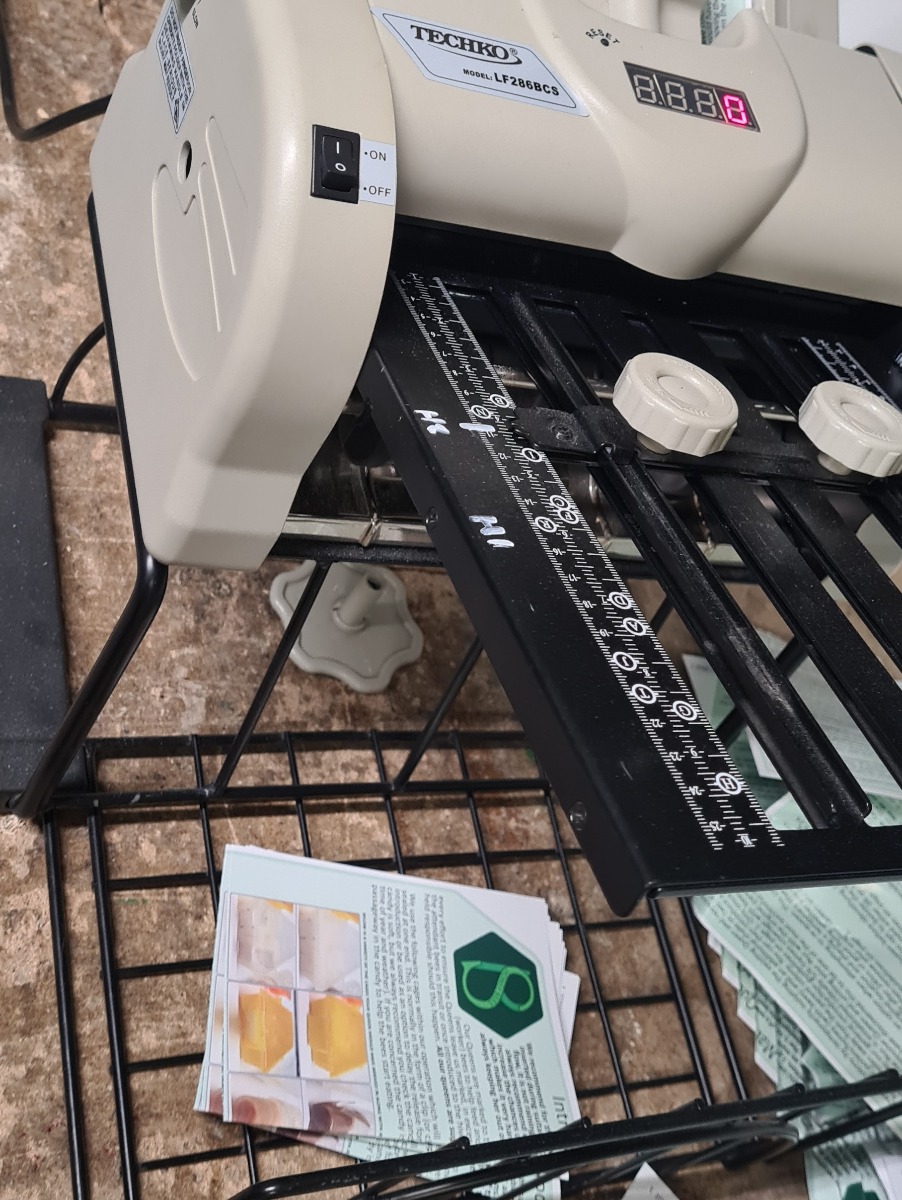

4. Folding Queen Introduction Leaflets:

Every detail matters, including the folding of Queen Introduction leaflets. These informative materials provide guidance for beekeepers as they introduce new queens into their colonies.

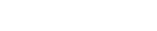

5. Preparing Queen Jiffy Bags:

Thousands of Queen Jiffy bags are prepared, ready to be dispatched during the upcoming season. This meticulous preparation ensures smooth operations when the demand for queens is at its peak.

6. Spraying Cedar Brood/Super Boxes:

To protect our hives from the elements, we spray newly assembled cedar brood and super boxes. This extra layer of protection helps to extend the lifespan of our equipment.

7. Construction Work:

Building upon last year's efforts, we continue construction work to enhance our facilities. The addition of a mezzanine level provides an insulated workshop area, essential for assembly and repair work during the winter months.

8. Hefting Bee Hives:

Regular checks on our colonies are essential, even in winter. We heft bee hives monthly, ensuring they have an ample supply of stores to see them through the colder months.

9. Preparing Poly Nucs:

Poly Nucs are prepared in anticipation of the following season. These smaller hives serve as nucleus colonies and are essential for expanding our bee populations.

10. Extraction Line Maintenance:

Maintenance is key to ensuring the smooth operation of our extraction line. We meticulously check and repair machines, ensuring they're ready to handle the season's harvest.

11. Stockpiling Granulated Sugar:

Finally, we stockpile granulated sugar, an essential resource for feeding our bees during times of scarcity. This preparation ensures that our colonies have the necessary sustenance to thrive.

While winter may offer a respite from the frenetic pace of the beekeeping season, it's a time of continuous work and preparation for us at BS Honey Bees Ltd. Despite the occasional break for Christmas and family holidays, our focus remains on completing tasks and improving efficiency. Our dedication to our craft drives us to meet deadlines and ensure that our bee farm operates smoothly year-round.

The winter of 2022 was particularly busy for us, as we moved into new premises and undertook extensive preparations for the 2023 season. Despite the challenges, we remained committed to our goal of delivering quality products and services to our customers.

So, next time you see a bee farmer, remember that their work is never truly done. Behind every jar of honey, nucleus colony or Queen Bee delivery, lies hours of dedication, preparation, and hard work, ensuring that our buzzing friends thrive and our business flourishes.